Mannacote has been gaining attention as an innovative material with a wide range of applications in modern construction, industrial uses, and sustainable development. From its unique composition to its versatile applications, Mannacote is quickly becoming a material of choice for architects, engineers, and industrial manufacturers. In this article, we will explore everything about Mannacote, from its properties and manufacturing process to real-world applications, benefits, and potential future developments.

Introduction to Mannacote

In the ever-evolving world of materials science, Mannacote stands out as a game-changer. Unlike traditional materials, Mannacote offers a blend of strength, durability, and environmental compatibility. Initially developed for industrial purposes, it has quickly found its way into construction, manufacturing, and even niche consumer products.

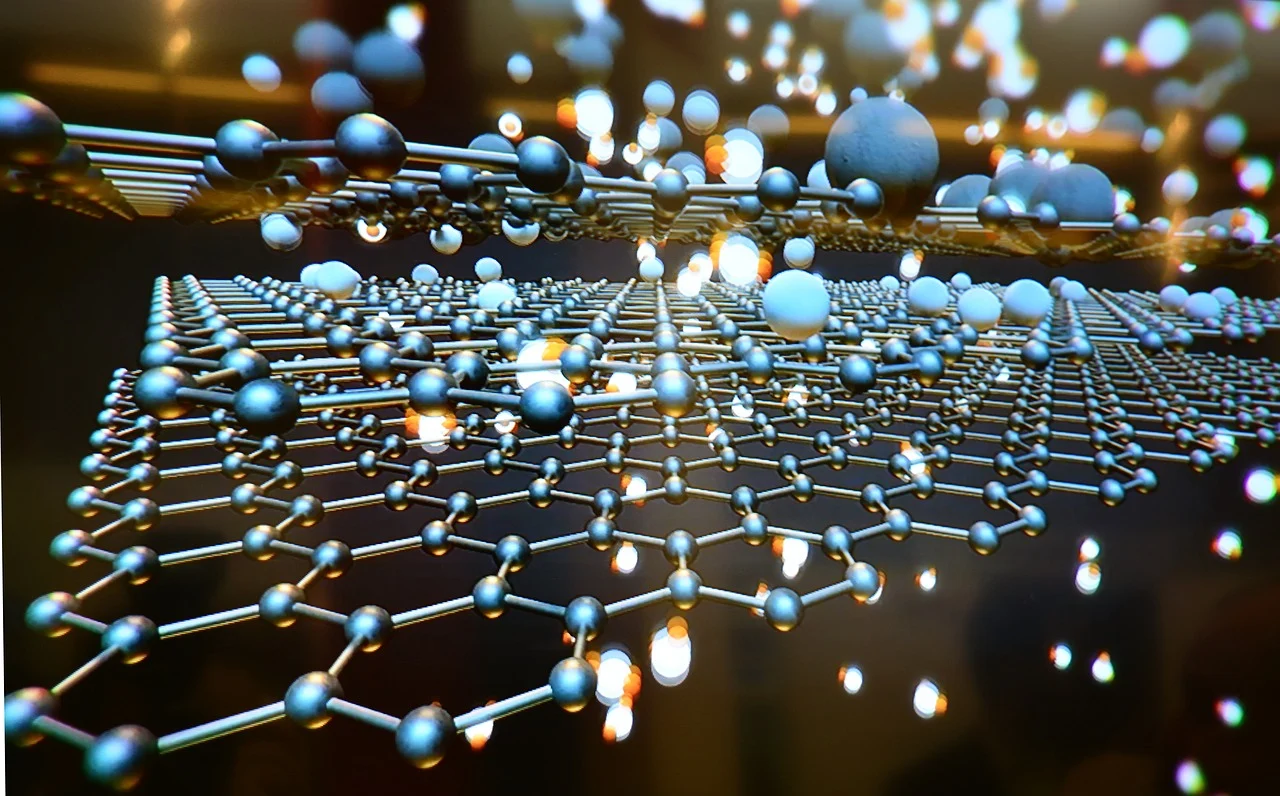

Mannacote is known for its unique molecular structure that provides resistance to heat, corrosion, and mechanical stress. Its versatility makes it ideal for applications where traditional materials like metals, plastics, or concrete may fall short.

The Origins and Development of Mannacote

The development of Mannacote dates back to early experimental material science initiatives. Researchers sought a material that could withstand extreme environmental conditions while being lightweight and cost-effective. Through extensive experimentation with polymers, ceramics, and composite blends, Mannacote emerged as a superior alternative.

Key milestones in Mannacote’s development include:

-

Initial Research: Scientists studied different combinations of organic and inorganic compounds to achieve maximum durability.

-

Prototype Creation: Early prototypes demonstrated excellent resistance to wear, heat, and chemical reactions.

-

Industrial Adoption: Once its performance was validated, Mannacote was adopted for industrial coatings and protective layers.

-

Commercial Use: Today, Mannacote is used in construction, electronics, automotive industries, and specialized consumer products.

Composition and Properties of Mannacote

One of the reasons Mannacote is celebrated is due to its unique composition. While the exact formula can vary depending on the intended application, the general characteristics remain consistent.

Key Properties:

-

Durability: Mannacote resists physical and chemical degradation, making it ideal for harsh environments.

-

Heat Resistance: Unlike many polymers, Mannacote withstands high temperatures without deforming or losing integrity.

-

Lightweight Nature: Despite its strength, Mannacote is relatively light, reducing structural load in construction and manufacturing.

-

Eco-Friendly Composition: Mannacote’s composition often includes recyclable components, making it sustainable.

-

Versatility: It can be adapted for coatings, sheets, panels, and composite materials.

These properties make Mannacote an ideal candidate for applications that demand both durability and environmental responsibility.

Applications of Mannacote

The applications of Mannacote span multiple industries. Its versatility is a significant factor in its growing popularity.

1. Construction Industry

In modern construction, Mannacote is used for:

-

Protective coatings for metal structures to prevent corrosion.

-

Durable panels for exterior and interior surfaces.

-

Lightweight composite materials for modular construction.

Architects and engineers appreciate Mannacote for its ability to combine strength with aesthetic flexibility, making it suitable for modern urban designs.

2. Industrial Uses

Industrial sectors leverage Mannacote for:

-

Machinery protective coatings.

-

Chemical-resistant linings.

-

Durable components in high-wear machinery.

Its heat and chemical resistance make Mannacote a preferred choice in factories and production lines.

3. Automotive and Transport

Automotive industries are increasingly incorporating Mannacote for:

-

Lightweight car panels.

-

Heat-resistant engine components.

-

Protective coatings for vehicle parts exposed to environmental stress.

This contributes to improved fuel efficiency and long-lasting vehicle performance.

4. Consumer Products

Though less common, Mannacote is now being used in high-end consumer products:

-

Durable kitchen appliances.

-

Protective smartphone cases.

-

Eco-friendly furniture panels.

Its adaptability to different forms and finishes makes Manna cote appealing for premium products.

Benefits of Using Manna cote

Using Manna cote offers multiple advantages:

-

Extended Lifespan: Manna cote-coated surfaces can last years longer than traditional materials.

-

Reduced Maintenance Costs: Its durability minimizes the need for frequent repairs.

-

Environmental Impact: Recyclable components reduce landfill waste.

-

Energy Efficiency: Lightweight properties reduce structural energy costs in construction.

-

Versatility: Can be tailored for specific industry needs.

These benefits explain why companies and professionals are increasingly turning to Manna cote for both practical and sustainable solutions.

Manna cote vs Traditional Materials

Comparing Manna cote to metals, plastics, and concrete shows its unique advantages:

-

Metal: Manna cote is lighter and corrosion-resistant without the need for additional coatings.

-

Plastic: Manna cote handles heat and mechanical stress better than conventional plastics.

-

Concrete: While concrete is strong, Manna cote provides comparable strength with less weight and greater flexibility.

This comparison highlights why Manna cote is considered a next-generation material in many sectors.

Manufacturing Process of Manna cote

The production of Manna cote involves advanced material science techniques. Though proprietary formulas differ, general steps include:

-

Raw Material Selection: Combining polymers, ceramics, or other composite elements.

-

Blending and Synthesis: Using controlled chemical reactions to create the desired molecular structure.

-

Shaping: Manna cote can be cast, extruded, or molded depending on the final product.

-

Curing: Applying heat or chemical treatments to stabilize the material.

-

Quality Testing: Each batch undergoes rigorous testing for durability, heat resistance, and flexibility.

Manufacturers emphasize precision in each step to ensure Manna cote meets strict performance standards.

Future of Manna cote

The future of Manna cote looks promising. With ongoing research, potential developments include:

-

Enhanced eco-friendly formulations using more recycled materials.

-

Applications in aerospace due to lightweight and heat-resistant properties.

-

Integration with smart technologies for adaptive coatings or self-repairing surfaces.

-

Expansion into everyday consumer goods and electronics.

As industries continue to prioritize sustainability and efficiency, Manna cote is poised to play a central role.

Case Studies: Manna cote in Action

Several projects have successfully implemented Manna cote:

-

Urban Buildings: Protective panels in skyscrapers reduced maintenance costs by 30%.

-

Automotive Manufacturing: Engine components coated with Manna cote lasted significantly longer under heat stress.

-

Industrial Machinery: Chemical-resistant linings improved equipment durability in factories handling harsh chemicals.

These examples highlight how practical and versatile Manna cote can be in real-world scenarios.

Challenges and Considerations

While Manna cote offers numerous benefits, certain considerations remain:

-

Initial Cost: High-quality Manna cote may have a higher upfront cost than conventional materials.

-

Specialized Manufacturing: Requires expertise and equipment for production.

-

Availability: Limited suppliers in some regions may affect accessibility.

Despite these challenges, the long-term advantages often outweigh the initial hurdles.

Manna cote in Sustainability

Sustainability is one of the key selling points of Manna cote:

-

Many formulations use recyclable components.

-

Lightweight properties reduce transportation energy costs.

-

Long-lasting durability minimizes waste from frequent replacements.

Companies focusing on green building and industrial practices increasingly rely on Manna cote as a sustainable choice.

Conclusion

Manna cote is more than just a material; it represents a leap forward in modern engineering and sustainable development. With its unique combination of durability, versatility, and eco-friendly properties, Manna cote is becoming indispensable across industries. From construction to automotive and consumer products, the applications are vast, and the benefits are clear. As innovation continues, Manna cote is set to redefine what we expect from materials in both industrial and everyday settings.

By investing in Manna cote, businesses and individuals alike can enjoy enhanced performance, reduced costs, and a smaller environmental footprint, making it a material truly built for the future.